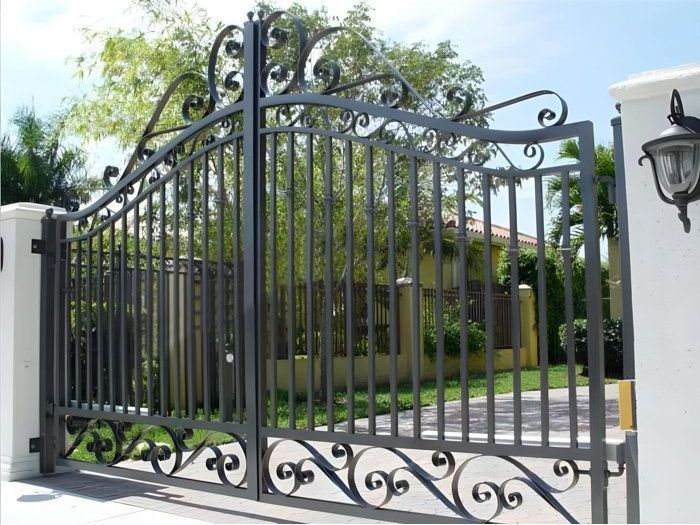

Metal Sliding Gate Tracks and Systems

Orange County Artesian Custom Iron Gates specializes in premium metal sliding gate tracks and systems that deliver reliable performance for residential and commercial properties. Our expertly engineered sliding gate systems provide smooth operation while maintaining the highest standards of durability and security.

With professional-grade metal sliding gate tracks designed to withstand heavy loads and continuous use, we create solutions that serve your property for decades. The typical sliding gate weighs about 250 pounds, requiring robust track systems that can bear this weight day in and day out while exposed to various environmental factors.

Our Metal Sliding Gate Track and System Services

We provide comprehensive sliding gate track solutions designed specifically for smooth operation and long-term reliability. Our systems ensure your gate functions properly while maintaining professional aesthetics and security standards.

Custom Track Design and Engineering

Our custom metal sliding gate track design process begins with thorough site evaluation to determine the optimal system for your specific requirements. We analyze soil conditions, gate weight, traffic patterns, and environmental factors that impact track performance.

Our engineers create detailed specifications that ensure proper load distribution and smooth operation throughout the gate's lifespan. Each track system is precisely calculated to handle your gate's weight plus additional safety margins for reliable operation.

The design process includes foundation requirements, drainage considerations, and alignment specifications that prevent premature wear. Our custom approach ensures every track system integrates seamlessly with your property's existing infrastructure and aesthetic requirements.

Professional Track Installation Services

Our certified installation teams use specialized equipment and proven techniques to ensure precise track positioning and secure anchoring. The installation process begins with accurate excavation and foundation preparation using laser-guided equipment for perfect alignment.

We install galvanized steel or aluminum tracks based on your specific requirements and environmental conditions. Each installation includes comprehensive testing of all mechanical components to ensure smooth gate operation before final commissioning.

Our technicians verify proper gate balance, alignment, and clearances throughout the entire travel path. The installation process includes detailed documentation and operator training to ensure optimal system performance.

Heavy-Duty Industrial Track Systems

For industrial applications, our heavy-duty metal sliding gate track systems handle gates weighing up to several thousand pounds. These robust systems feature reinforced steel construction.

The tracks utilize sealed bearing assemblies that require minimal maintenance. Each system includes integrated drainage features that prevent water accumulation and debris buildup.

Types of Metal Sliding Gate Track Systems

Understanding the various track system options helps ensure you select the optimal solution for your specific gate application and operational requirements.

Ground-Level Track Systems - Traditional embedded tracks that provide stable guidance for heavy gates while maintaining low profile installation. These systems work well for level surfaces and moderate traffic applications. The tracks can be installed flush with pavement or slightly recessed to prevent debris accumulation.

Cantilever Track Systems - Advanced systems where the gate is suspended from track-mounted carriages without ground contact, eliminating wear from debris and uneven surfaces. These systems provide smooth operation regardless of ground conditions and reduce maintenance requirements significantly.

Overhead Track Systems - Space-efficient solutions where the gate hangs from overhead track assemblies, perfect for areas where ground-level tracks aren't practical. These systems can accommodate gates up to 2,200 pounds while providing unobstructed ground clearance.

V-Groove Track Systems - Precision-engineered tracks with V-shaped profiles that provide superior wheel guidance and reduced friction for exceptionally smooth operation. These systems work excellent for high-frequency operations and applications requiring quiet performance.

Dual Track Systems - Heavy-duty configurations using parallel tracks to distribute load and provide enhanced stability for extra-wide or heavy gates. These systems ensure even weight distribution and extended operational life for demanding applications.

Materials and Construction Options

Galvanized Steel Tracks - Premium corrosion-resistant steel construction that provides maximum strength and durability for heavy-duty applications. The galvanized coating protects against rust and environmental degradation while maintaining structural integrity under extreme loads.

Aluminum Track Systems - Lightweight yet durable aluminum construction ideal for residential applications and environments where corrosion resistance is critical. These tracks offer excellent strength-to-weight ratios and require minimal maintenance throughout their operational life.

Stainless Steel Options - Premium stainless steel construction for coastal environments and applications requiring the highest level of corrosion resistance. These systems maintain their appearance and performance even in harsh marine environments with salt air exposure.

Powder-Coated Finishes - Protective and decorative coatings available in various colors to match your property's aesthetic requirements while providing additional corrosion protection. These finishes maintain their appearance for years with minimal maintenance requirements.

Sealed Bearing Assemblies - Maintenance-free bearing systems that provide smooth operation without regular lubrication requirements. These components are designed for extended operational life even in dusty or harsh environmental conditions.

FAQs

We provide clear answers about materials, designs, costs, installation times, maintenance, and warranties. Our goal is to help you make informed choices for your gate project.

What factors determine the type of metal sliding gate track system I need?

The selection depends on your gate's weight, size, traffic frequency, and environmental conditions. Gates under 500 pounds work well with standard ground-level tracks, while heavier gates require cantilever or dual-track systems. Our engineers evaluate these factors during site assessment to recommend the optimal track system for your application.

How long do metal sliding gate tracks typically last with proper maintenance?

High-quality metal sliding gate tracks last 15-25 years with proper maintenance and appropriate system selection. Galvanized steel tracks provide the longest service life, while aluminum systems offer excellent durability in less demanding applications. Regular cleaning, lubrication, and inspection significantly extend track system life.

What maintenance is required for metal sliding gate track systems?

Regular maintenance includes monthly track cleaning, quarterly lubrication of bearing assemblies, and annual hardware inspection. Track alignment should be checked periodically to prevent uneven wear patterns. Professional maintenance services can identify potential issues early and perform adjustments to prevent costly repairs.

Can existing sliding gates be retrofitted with new track systems?

Yes, most existing sliding gates can be upgraded with new metal track systems, though some modifications may be necessary. Our engineers evaluate existing gates to determine compatibility and identify required modifications. Retrofitting often improves performance significantly while extending the gate's operational life.

How do I know if my sliding gate tracks need replacement?

Signs indicating track replacement include visible wear grooves, rough gate operation, frequent derailments, and excessive noise. Rust or corrosion damage and repeated maintenance problems also suggest replacement is needed. Professional inspection can assess track condition and determine whether repair or replacement is more cost-effective.